Address: No.14 Waihuan Road, CBD, Zhengzhou, China

Tel: +86-15978414719

Fax: +86-371-65621393

Mail: sale@alumhm.com

Time:2024-09-25

Al-Cu-Mg alloys are one of the most important alloy families of heat-treatable aluminum alloys. The most widely used alloy of this type in aircraft structures is 2024 aluminum alloy. The hardness of 2024t3 aluminum alloy is about HB120, and 2024t4 aluminum alloy reaches about HB140.

2024 aluminum alloy is an aluminum alloy with copper as the main alloying element. It is used in applications that require a high strength-to-weight ratio and good fatigue resistance. It can only be welded by friction welding and has moderate machinability. Due to its poor corrosion resistance, it is usually protected with aluminum or Al-1Zn cladding, although this may reduce fatigue strength.

2024 aluminum alloy is mainly used in aircraft structures with high strength requirements, such as fuselage, wings, belly plates, etc. In addition to high toughness, 2014 aluminum alloy also has many advantages such as stress corrosion resistance and fatigue resistance, so it is often used in the manufacture of civil aircraft such as Boeing and Airbus. 2224 aluminum alloy is a product obtained by further optimization of 2024 aluminum alloy.

7075 alloy is a heat-treatable and strengthened high-strength deformable aluminum alloy of aluminum-zinc-magnesium-copper system. It is the elder of super-hard aluminum. The common tempers are 7075 t6 aluminum and 7075 t73 aluminum.

It is used to manufacture various structural parts, especially aerospace structural parts. It is the most widely used high-strength aluminum alloy today.

In the state of solid solution treatment and artificial aging T6, the plasticity of 7075 alloy is slightly lower than 2024T6 and slightly higher than 7A04T6. The plate is notch-sensitive to static fatigue and has better stress corrosion performance than 7A04.

In order to enhance its corrosion resistance, it needs to be over-aged. The common treatment is T73, that is, the aluminum alloy is firstly solid solution treated, and then double-stage aging treatment is performed (after heating and keeping warm at a lower temperature for a period of time, then heating and keeping warm at a higher temperature for a period of time).

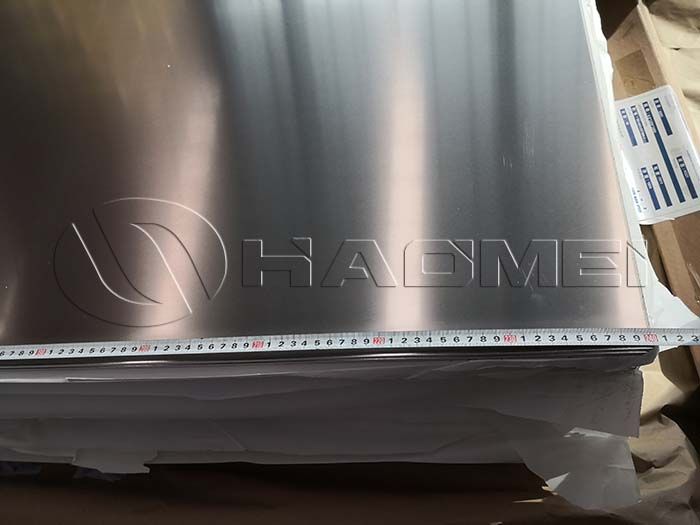

After this treatment, although the tensile strength of the material decreases by about 15%, the material's stress corrosion resistance and intergranular corrosion resistance are greatly improved. Haomei Aluminum has both 7075 and 2024 aluminum sheet. Welcome to leave message below to inquire what you need.