Address: No.14 Waihuan Road, CBD, Zhengzhou, China

Tel: +86-15978414719

Fax: +86-371-65621393

Mail: sale@alumhm.com

Time:2025-10-24

Among aluminum alloys, 7000 aluminum alloys have become a star material in aerospace, high-end manufacturing, and other fields due to their outstanding strength properties. These alloys, primarily composed of zinc and often reinforced with magnesium and copper, not only possess exceptionally high tensile strength but also boast mechanical properties that can be further enhanced through heat treatment. They also maintain a balance between corrosion resistance and workability.

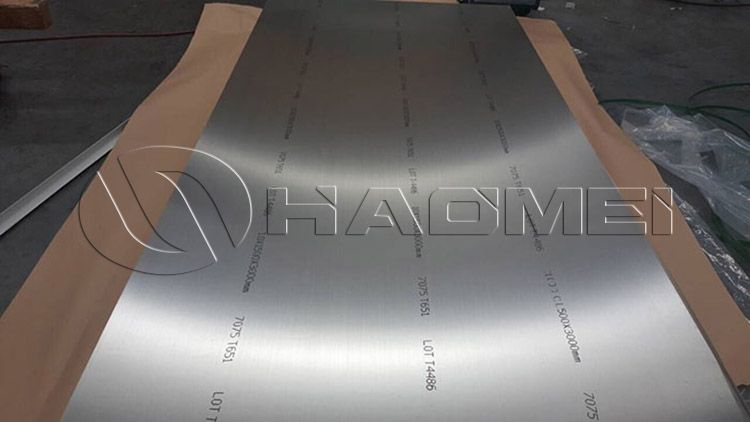

In terms of composition, 7075 sheet contains approximately 5.1%-6.1% zinc, 2.1%-2.9% magnesium, and 1.2%-2.0% copper. It also contains small amounts of impurities such as silicon and iron.

This compositional combination allows it to achieve a tensile strength exceeding 570 MPa and a yield strength exceeding 500 MPa after T6 heat treatment (solution treatment followed by artificial aging). Its hardness far exceeds that of ordinary aluminum alloys, even rivaling that of some steels.

In terms of application scenarios, 7075 aluminum is primarily used in areas requiring extremely high strength. In the aerospace industry, many critical load-bearing structures, such as aircraft wing spars, fuselage frames, and landing gear components, are manufactured using 7075 aluminum alloy, as it reduces weight while ensuring the fuselage's load-bearing capacity.

In high-end sports equipment, bicycle frames, snowboard bindings, and rock climbing equipment are also commonly made of 7075, which is lightweight yet can withstand the impact of intense exercise. Furthermore, 7075 is also chosen for its high strength in industrial molds, high-pressure vessels, and precision machinery parts.

However, it should be noted that 7075's corrosion resistance is relatively average, and it is particularly susceptible to stress corrosion cracking in humid or salty environments. Therefore, surface treatments such as anodizing and painting are often required to enhance its corrosion resistance.

7050 aluminum alloy was developed to meet the higher material requirements of the aerospace industry. It offers an excellent balance of strength, toughness, and corrosion resistance, making it a common material for high-end equipment such as large passenger aircraft and military aircraft. In terms of composition, 7050 aluminum alloy contains 5.7%-6.7% zinc, 2.0%-2.6% magnesium, and 1.9%-2.6% copper. Compared to 7075 alloy , the higher copper content allows it to achieve superior overall mechanical properties after heat treatment.

After T7451 heat treatment (solution treatment followed by tensile straightening and artificial aging), 7050 aluminum alloy achieves a tensile strength of approximately 510 MPa and a yield strength of approximately 455 MPa. While slightly lower in strength than 7075, it boasts higher fracture toughness and greater resistance to stress corrosion cracking, making it more resistant to complex loads and harsh operating conditions.

In terms of application, 7050 aluminum plate is primarily used in the aerospace sector. For example, large passenger aircraft like the Boeing 787 and Airbus A350 utilize extensively 7050 aluminum alloy for large, load-bearing components such as fuselage skins and wing panels. This alloy not only withstands the aerodynamic loads and structural weight of the fuselage, but also resists corrosion from high-altitude low temperatures and humidity fluctuations.

In military aircraft, 7050 aluminum sheet is also used in fighter fuselage frames and missile body structures to ensure equipment reliability under high-speed flight and combat shocks. Furthermore, 7050 is used in high-end molds and marine engineering equipment, playing a vital role in applications requiring both strength and corrosion resistance.

If 7075 and 7050 focus on "ultra-high strength," 7005 aluminum alloy emphasizes "cost-effectiveness and practicality." It strikes a good balance between strength, weight, and processability, and is widely used in civilian industry and general structural applications. 7005 aluminum alloy contains 3.0%-4.0% zinc, 1.0%-1.8% magnesium, a low copper content (≤0.25%), and a small amount of manganese (0.20%-0.70%). This compositional design ensures that, while its strength is lower than that of 7075 and 7050, it still achieves a high level of strength.

After T6 heat treatment, it achieves a tensile strength of approximately 310 MPa and a yield strength of approximately 276 MPa. Its density is also low (approximately 2.78 g/cm³), offering significant lightweight advantages. 7005 also exhibits excellent weldability, allowing for connections using methods such as argon arc welding. Its processing and forming capabilities are also lower than those of the high-copper 7-series alloys, making it suitable for the manufacture of complex structural components.

In its diverse applications, 7005 aluminum alloy is used in a wide range of civilian applications. The most common application is in the bicycle industry, where mid- to high-end bicycle frames often utilize 7005 aluminum alloy. This alloy ensures load-bearing capacity and fatigue resistance while reducing vehicle weight and enhancing the riding experience.

In the automotive sector, 7005 is used in luggage racks, door frames, and chassis supports, contributing to vehicle lightweighting and lowering fuel consumption. It is also used in aluminum alloy scaffolding, outdoor furniture, and sports equipment (such as tennis racket frames), excelling in civilian structures requiring a balance between strength and lightweight.